In this article, we'll discuss every aspect of spider cranes — what they are, how they work, how much they lift, how high they lift, their components, operating procedures, and their benefits and limitations. They truly are one of the weirdest and most wonderful cranes in construction.

Get quotes for spider cranes

What is a spider crane?

A spider crane is a type of crane that is often used in construction and other industrial applications, which is kind of rare. It gets its name from its spidery shape; which includes a long boom (for lifting), crawler tracks that allow it to maneuver around obstacles in tight spaces, and spider legs that hold it steady during the lifting process.

Spider cranes are very versatile and can be used for lifting heavy objects in tight spaces, including indoors, on the top of buildings, and in all places traditional cranes can't go. If you want more information about other types of cranes, follow the link.

How does a spider crane work?

A spider crane is a type of lightweight mini crawler crane that gets its name from its unique appearance. It has a long boom, a compact body, and multiple legs that allow it to move around obstacles. It's sturdier than a mini crawler because the expanding legs or props give the crane extra ballast and stability.

This also means the crane can be parked on slightly uneven ground and can conduct a lift from an angle, whereas crawler cranes generally have to be on completely flat ground to operate.

A fine line-up of spider cranes courtesy of Sydney Cranes.

Due to their flexible operation, spider cranes are most commonly used in commercial construction but can also be used in manufacturing, warehousing, and even film production. You'll see spider cranes in any commercial situation where a crane has to enter an enclosed space and lift heavy objects. Literally, the applications are endless.

What does a spider crane do?

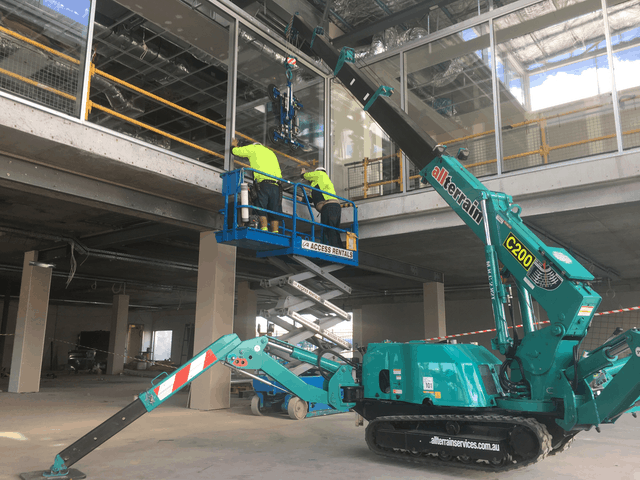

Image courtesy of iseekplant supplier All Terrain Services - a spider crane working inside of a high-rise building lifting glass doors into place.

A spider crane rolls into a confined construction area on its tracks. The rigger then pops out its 3-4 legs and places them on the ground, adjusting distance and height on the X and Y axes to ensure the crane touches as many parts of the stable ground as possible. As mentioned, the legs provide more stability when operating on uneven or sloped ground, but the safest way to operate a spider crane is on flat ground (like all cranes, really).

Usually, the combination of the weight of the lifting item and the height it's being lifted determines how far the legs are extended to ensure the rigger has created sufficient ballast. Many of the legs are operated by hydraulics, which also lends additional grunt to the lifting process.

Once positioned safely, the rigger will undertake safety checks and complete lifting safety paperwork before affixing the load to the boom and lifting. The spider crane then proceeds to lift loads up to its maximum carrying capacity and height for that specific load (as specified by the size of the spider crane you've used).

You'll see spider cranes prolifically used in the later stage of building large high-rise buildings as they are clever at lifting building materials multiple floors to higher levels as the building is being built out.

What are the components of a spider crane?

The main component of a spider crane is the boom, typically made from aluminium or steel. The boom is attached to the crane's base via several pulleys and cables. At the end of the boom is a hook, which is used to attach the crane's load. The hook is operated by a hydraulic system that allows it to be raised and lowered.

These cranes work by using hydraulics to lift and move heavy objects. The operator uses a remote control to operate the crane's hydraulic pumps, which power the crane's lifting and movement.

The legs of a spider crane are also hydraulic, which allows the crane to move around obstacles and into tight spaces. Each leg has its wheel, which helps the crane to move over uneven terrain.

How much can a spider crane lift?

Spider cranes can't lift much compared to Franna cranes, crawler cranes, all-terrain cranes, city cranes, rough terrain cranes, slew cranes, or tower cranes. The largest spider crane in Australia maxes out at 10 tonnes, but there are variants across the world that are capable of lifting 25 tonnes. While they don't have massive payloads, it doesn't matter because spider cranes are perfect for their manoeuvrability in tight spaces, over their lifting payload grunt.

How high can a spider crane lift a load?

Spider cranes often have very long booms, but that doesn't mean they can carry their maximum payload the full length of their boom (as the crane would tip). For example (just to use round numbers), a spider crane with a maximum tonnage capacity of 10 tonnes and a boom that extends 22m can only lift the full 10 tonnes up to 3m maximum. That said, it can lift much smaller loads right up to the extended height of 22m.

So, when you're reading the spec sheet of a spider crane, you will often notice that the max weight capacity is expressed as 10t x 3m. That means it can carry a max load of 10 tonnes up to 3m but can lift smaller loads to its 'maximum lifting height'.

The biggest spider cranes in the world have a maximum lifting height of 25 - 30 meters, but they are rare. Read this article about the biggest cranes in the world.

How do you operate a spider crane?

Operating a spider crane requires a high degree of skill and training. The operator, usually called a rigger, must be able to control the crane's movements precisely to avoid accidents, as well as be able to complete the comprehensive procedural process required to lift anything on an Australian job site. Most crane operators and riggers must complete a lifting study before lifting anything.

This is a lengthy risk assessment study of the lifting conditions (including weather, ground stability, and other interactions) and safety hazards before operating. After that, the site manager needs to sign off on that study.

After completing the procedural aspects of the lift and once all workers on the site are notified that a lift is taking place, the rigger attaches the load to the crane's hook. The rigger or certified operator working at the rigger's instruction, then uses the remote control to operate the hydraulic pumps, which power the crane's lifting and movement. Working at heights is the most dangerous aspect of all construction work. Read more about licensing for cranes.

When moving the load, the operator must be careful not to swing it too widely, as this could damage nearby property or injure people. The operator must also be aware of the crane's surroundings at all times to avoid accidents. If any of the lifting conditions change, the lifting ceases, and a new lift study is prepared before it recommences. Read more about safety tips for cranes.

What are the benefits of a spider crane?

Image courtesy of iseekplant supplier AMC Hire - two small spider cranes working on an industrial site.

Image courtesy of iseekplant supplier AMC Hire - two small spider cranes working on an industrial site.

Spider cranes offer a number of advantages over traditional cranes. Their compact size means they are more versatile and can be used in confined spaces, such as inside buildings, which makes them really the only crane ideal for indoor use. Spider cranes can be used in locations where all other cranes would not fit.

The reality is that there are some construction situations where a spider crane is your only option because the space is so confined or tight that no other type of mobile crane would enter the space, and the load is bigger than what an EWP or scissor lift is licensed to lift.

What are the limitations of a spider crane?

Despite their many advantages in tight space applications, the spider crane's major limitation is that their lifting capacity ends, where the capacity of most Frannas and other mobile cranes begins. Their lack of weight and size really limits their payload capacity. Another disadvantage of spider cranes is that they are more expensive than traditional cranes.

Because they are expensive, they are also rare and difficult to find in regional areas in Australia. They are more likely to be found in cities because more construction occurs in confined spaces or areas of high urban development.

So, do I need a spider crane on my job site?

Well, if your job is in a confined space that is difficult to get into, and you need to lift a load that exceeds the capacity of other types of elevated work platforms or lift and shift gear, then you probably need a spider crane.

If you need a crane that can maneuver around tight spaces and lift heavy loads, a spider crane is the right choice.

Related Articles:

- Best Franna Crane Brands

- What is a Franna Crane?

- Crane Hire Rates Guide

- 6 Things to Know Before Hiring a Crane